It's funny to be invited to F.P. Journe's new state-of-the-art dial and case manufacturers, Les Cadraniers and Les Boîtiers de Genève case and dial, and be told that all these things I'm about to show you—the tens of millions of Swiss Francs invested in equipment, custom-designed facilities, and talented staff—will not increase the brand's total production.

F.P. Journe will continue to produce around 1,000 mechanical watches annually, plus approximately 500 of its quartz Élégante models. Its new building in Meyrin, outside of Geneva, was inaugurated last year, housing dial and case manufacturers solely owned by Journe and representing decades of Journe's dedication to in-house watchmaking in a way few other brands have achieved. But these new facilities were designed with very little extra space for expansion. In fact, the basement of Les Boîtiers de Genève only has enough room to house a few upgraded machines in the future. Sure, a limiting factor is the footprint of its main headquarters in Geneva's old town, where movements are made and assembled. But that really doesn't matter. The company knows its goals and is all-in on where its production stands while making some of the best watches on the market today.

F.P. Journe's Manufacture and headquarters in a historic building of Old Town Geneva.

That's quintessential "Journe." The man and his company –Montres Journe SA – have been stable forces in the Swiss watch industry, setting the tone for a specific type of slow, meaningful growth for an independent brand. And yet, despite the industry's recent rise (and customers' nearly insatiable demand for the brand), there's one simple fact about Journe: the more things change, the more things remain the same. For Journe, growth has always been more about innovation than expansion.

As we begin our tour, I'd encourage you to read through this story in parts because it is both long and in-depth. Often, brands are unable to give time or unwilling to give access to cover nearly every part of their manufacturing. In this case, F.P. Journe completely opened its doors for this story over the course of two days earlier this spring and I'm happy to be able to take you along on the tour.

The Headquarters And Old Town Manufacture

To say that nothing has changed just because the brand hasn't increased production misses the core of what F.P. Journe stands for. Journe continues to carry on as a link to the greats of the past and the potential of the future, marrying manufacturing technology with innovating on core principles of horology that go back centuries. His heroes, Antide Janvier, Abraham-Louis Breguet, Jean-Antoine Lépine, and even mentor George Daniels, all exist in some way in the watches Journe makes.

Unlike most independent watchmakers (and some major brands) who rely on various outside suppliers, almost all the parts of each mechanical Journe watch are made in-house. Not only does Les Cadraniers make dials for F.P. Journe, they still do dial restoration for other brands (which you can read about in this article by Phillips) and modern dial manufacturing for them as well. At this point, the only components not made by the brand are crystals, springs, jewels, some parts of escapements, and straps. Even the circuitry for the Élégante is made in Switzerland. But I'm getting a bit ahead of our tour.

At the F.P. Journe headquarters, you're still greeted by the incredible astronomical clock made by C.L. Detouche in 1855 and restored over three years by the Musée International d'Horlogerie of La Chaux-de-Fonds. In the background is the late Jean-Claude Sabrier's extensive library.

The lounge in the entry at the headquarters.

Beyond the increased demand, there are plenty of other major changes that have happened in the last decade. If you look back at our visit to the manufacture in 2015, the first thing that jumps out is that the Maison is no longer making their iconic Sonnerie Souveraine, which was a mainstay of the brand since 2006. François-Paul himself decided in 2018 that part of what made their (at the time) most complicated watch special was its limited production – just over 50 pieces were made – and the watch was discontinued in 2019.

Instead of shutting down one revenue stream, that discontinuation opened the door to other complicated watches like the Astronomic Souveraine (one, if not the most complicated watch I've ever gone Hands-On with) and the FFC. Such watches would have been unimaginable to people like Janvier or Breguet – maybe even Daniels – and are only possible because Journe adopted modern industrial manufacturing technology like CNC machines to push his watches to the limit. The brand's total production number wouldn't be possible otherwise. But looking at his watches, you can see an appreciation of the balance of handcraft (when appropriate) and industrialization (when necessary), done at a scale that no other traditional independent has reached.

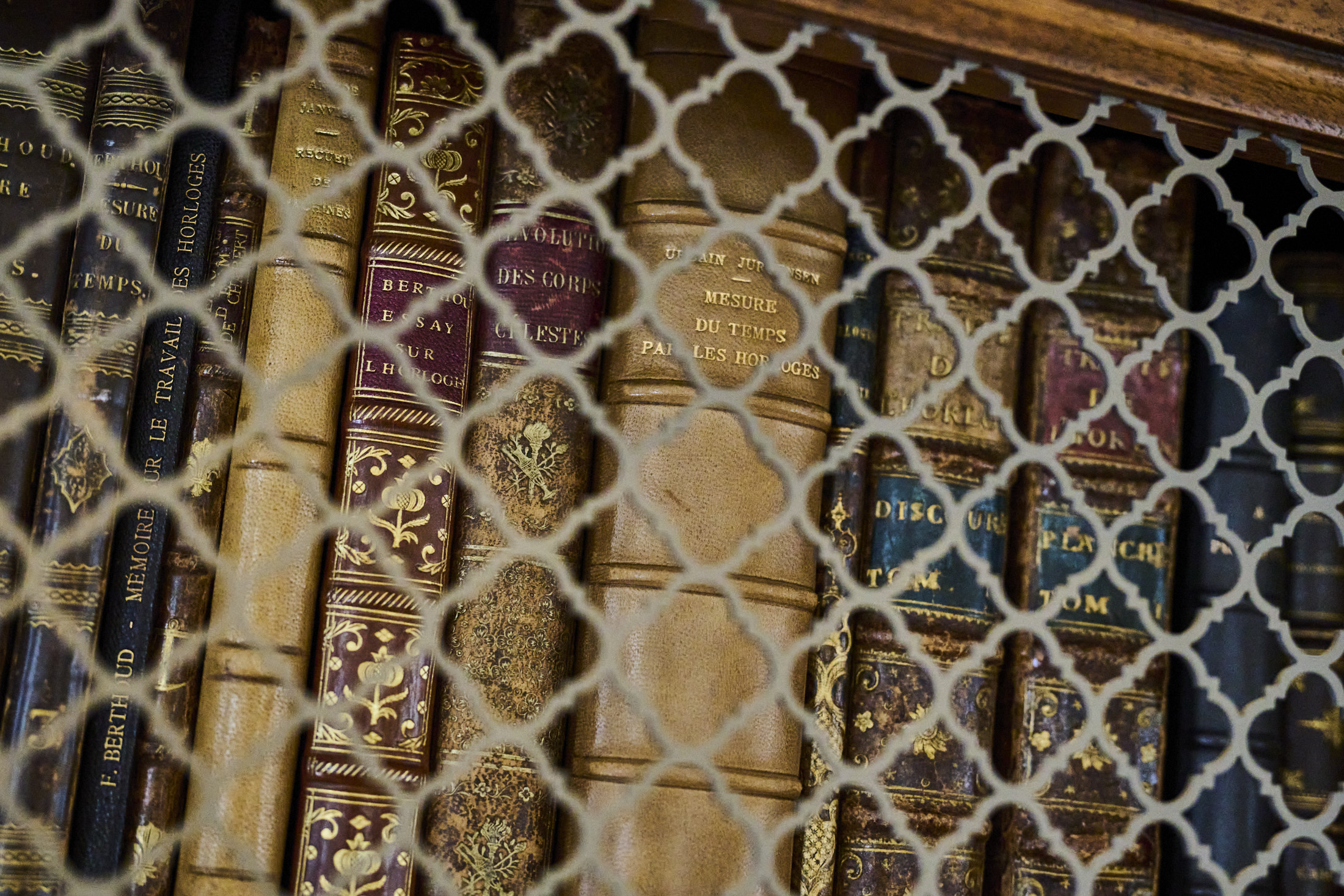

A selection of books from the Library of Jean-Claude Sabrier, an international horological expert and distinguished historian, which F.P. Journe purchased, buying every single one of the 273 lots (almost one thousand books) at a 2015 auction for CHF 760,000.

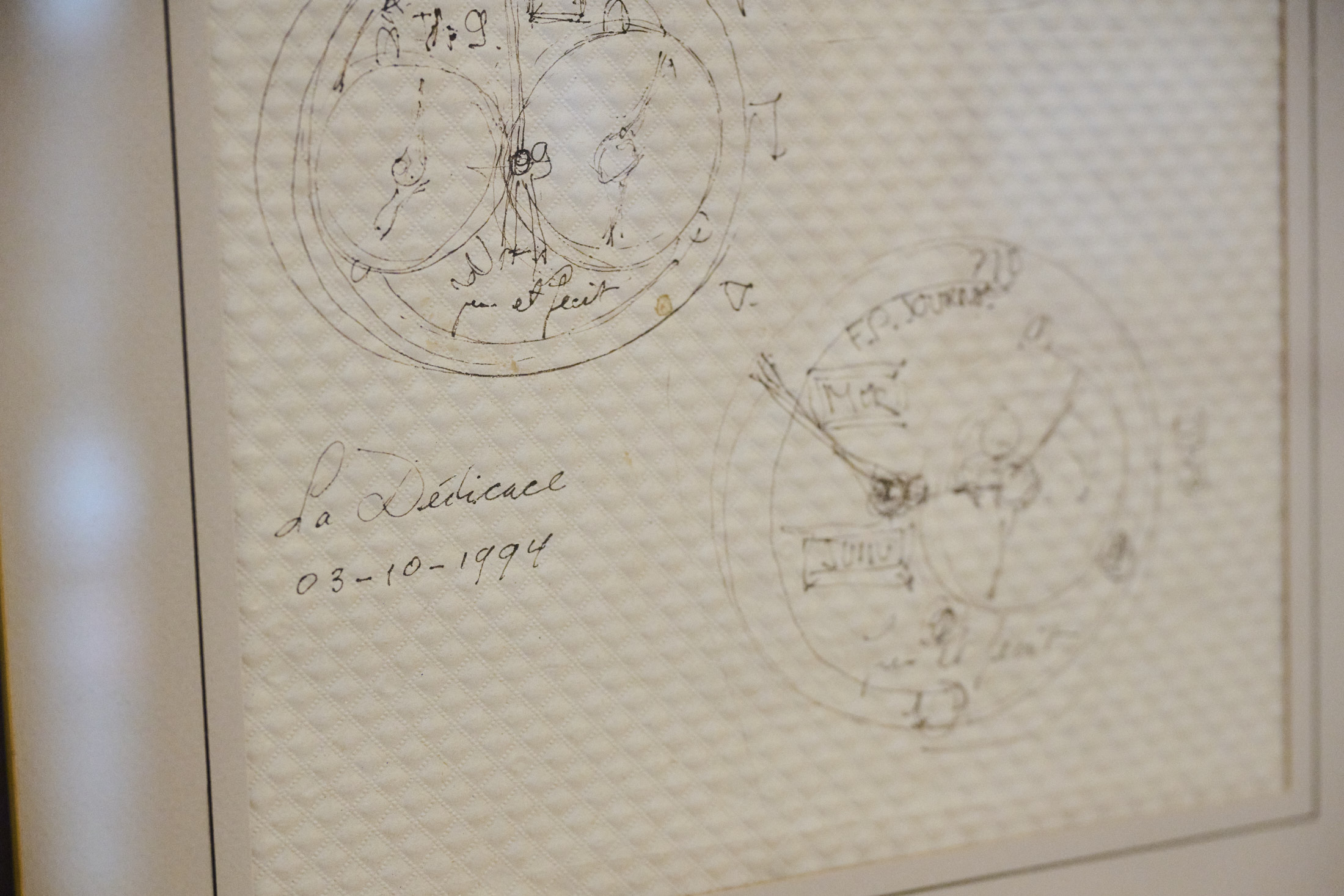

A signed and dated sketch from F.P. Journe of the design for the Octa Calendrier on the bottom right, and the first Chronomètre à Résonance on the left.

Handcraft is still, thankfully, very necessary. I often hear collectors criticize that Journe doesn't have the best movement finishing for its price. That's true. The brand will readily admit as much. But that's only because that's not where it put its efforts. Instead, they choose to spend time, money, and manpower on horological innovation. They do hand finishing, of course, but the goal is to not be another Dufour or Rexhepi – Journe is, well, Journe.

F.P. Journe employs about 150 people at its Swiss facilities. But in the company only three employees (four, including F.P. Journe himself) can assemble these two previously-mentioned incredibly complicated watches (the Astronomic and FFC). Yet, Journe keeps innovating and adding new challenges to his team's plate. A part of François-Paul's historic success is making a new caliber yearly. Such work requires that he continue coming to work at the headquarters on Rue de la Synagogue in Geneva, the location most people would see if they go to visit Montres Journe in Geneva. The inside remains much the same as our last trip in 2015. It's comforting, in a way, to know that no matter how much demand for the brand has grown, the core remains the same.

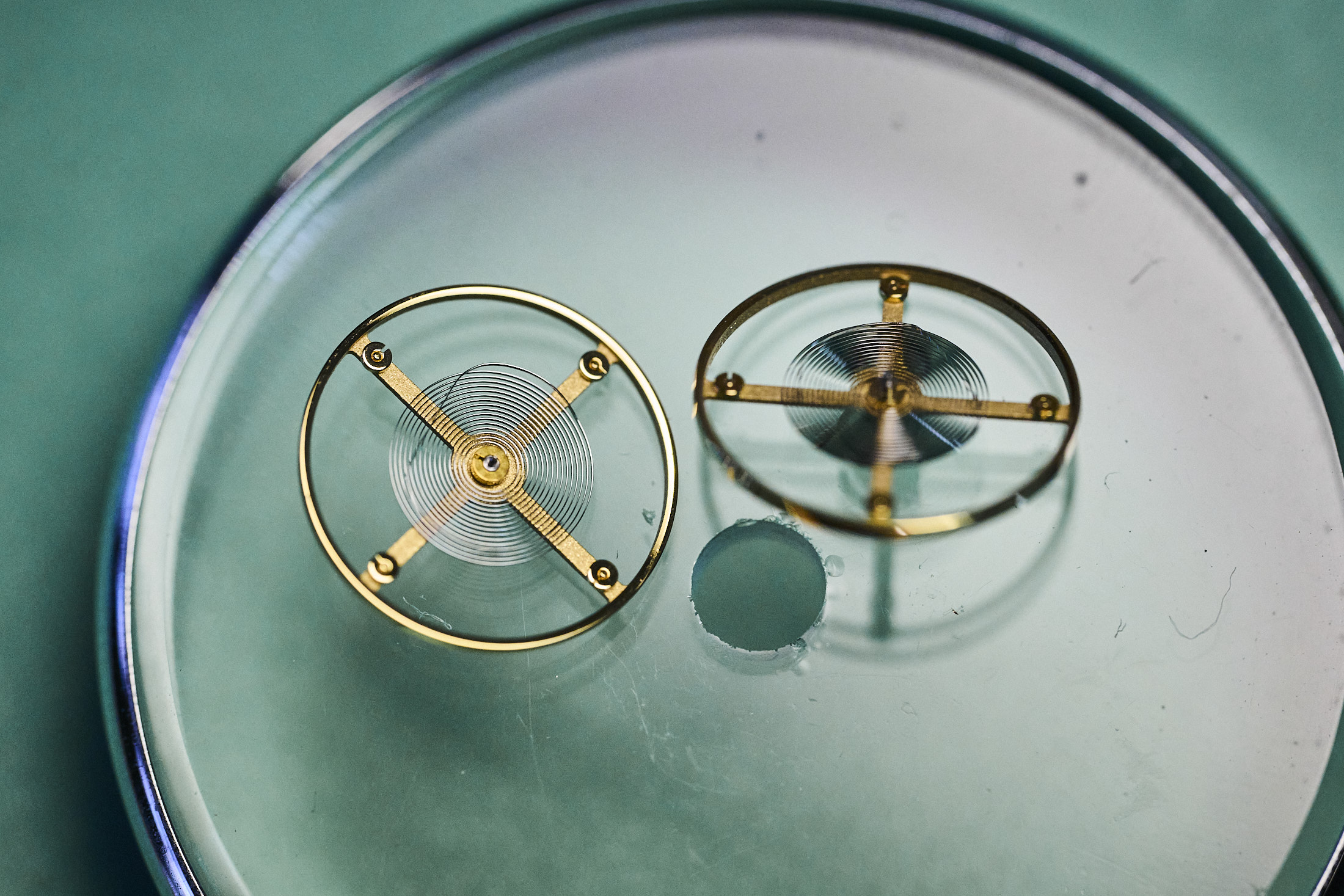

In 2002, F.P. Journe acquired this amazing collector's item: a double-pendulum resonance regulator manufactured by French watchmaker Antide Janvier in 1780. Journe calls this his link between his Chronomètre à Résonance and the 18th Century watchmaking that inspired him (and others, like Abraham-Louis Breguet). The clock now sits (very understated) in a conference room off the main entry. Three such clocks are known – the other two are in the Patek Philippe Museum in Geneva and the Musée Paul-Dupuy in Toulouse, though they are table clocks and not wall clocks.

In the basement of the main F.P. Journe building sit the CNC and electro-erosion machines that are responsible for the majority of the parts that make up the movements for their watches.

This machine performs the circular-graining finish on many of the bridges and plates. The brand still does this finishing by hand on the Astronomic Souveraine and the FFC, for example.

Movement plates sitting in a tray.

A selection of movement plates are evaluated with special tools matched to each individual hole to make sure they're milled to the exact size. Every plate otherwise goes through a Vertex camera, which enables precise controls down to the micron.

Components for watches machined with electro-erosion, where an electrically charged wire (fed from a spool) cuts through pieces of metal. At the right, above, you can see a gong for one of the brand's chiming watches.

A metal component for the dial of the Centigraphe.

You can see the electro-erosion machine on the left with the blue spool of Tungsten wire.

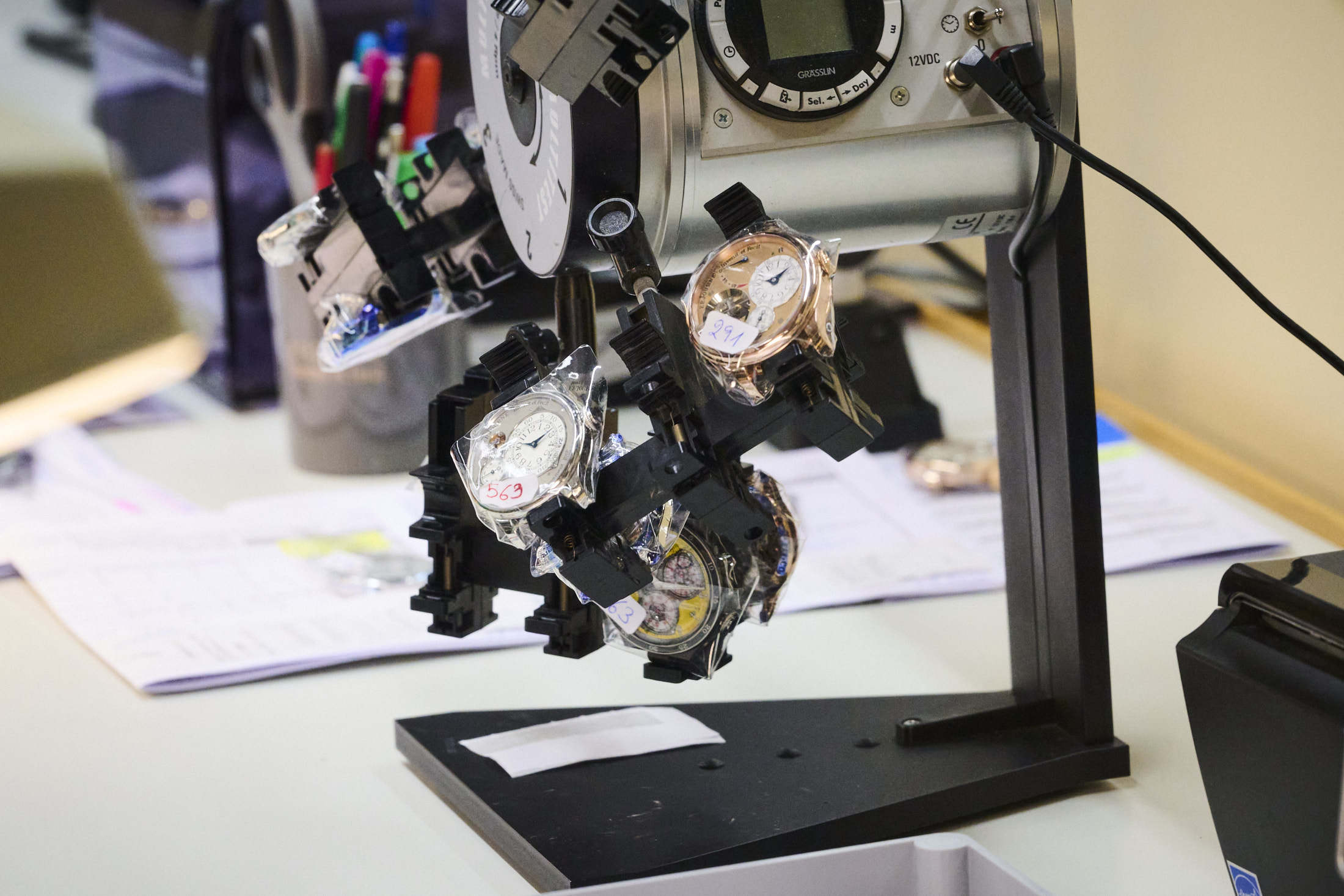

This is the final control room. When the watchmakers have finished assembling the watches, they are meticulously checked (aesthetic, functional and water-resistance checks).

This is the second mechanical workshop, where the brand manufactures the so-called revolutionary components: pivot, pinion, screw, axle, wheel, etc. using CNC lathes. F.P. Journe uses metal bars such as steel, brass and titanium to manufacture these components.

Making screws

#22 / This person is responsible for the jeweling of the movement, i.e. fitting the various rubies.

We moved on to the hand-finishing department. Not all components are hand-finished but here you'll see a member of the team polishing beveling a flying "égalité" bridge with a file.

Polishing the edge on a movement plate with a buffing machine.

Preparing to do perlage.

The upstairs hallway of F.P. Journe's old town manufacture, where each individual room is dedicated to one or more models, just as each watch is assembled from start to finish by a single watchmaker. R&D is in the basement, and after-sales service is in a large workshop at the end of this floor.

F.P. Journe Master Watchmakers Christophe and Laurent are the two men responsible for building the most complicated watch currently made by F.P. Journe, the Astronomic Souveraine.

Here you can see the watch is already in progress being assembled. This is the side you'll see through the caseback of the watch.

From the front you'll see the outer ring for the length of day fro sunrise to sunset with the sapphire day/night disc.

Christophe...

and Laurent.

And the tools to get the job done.

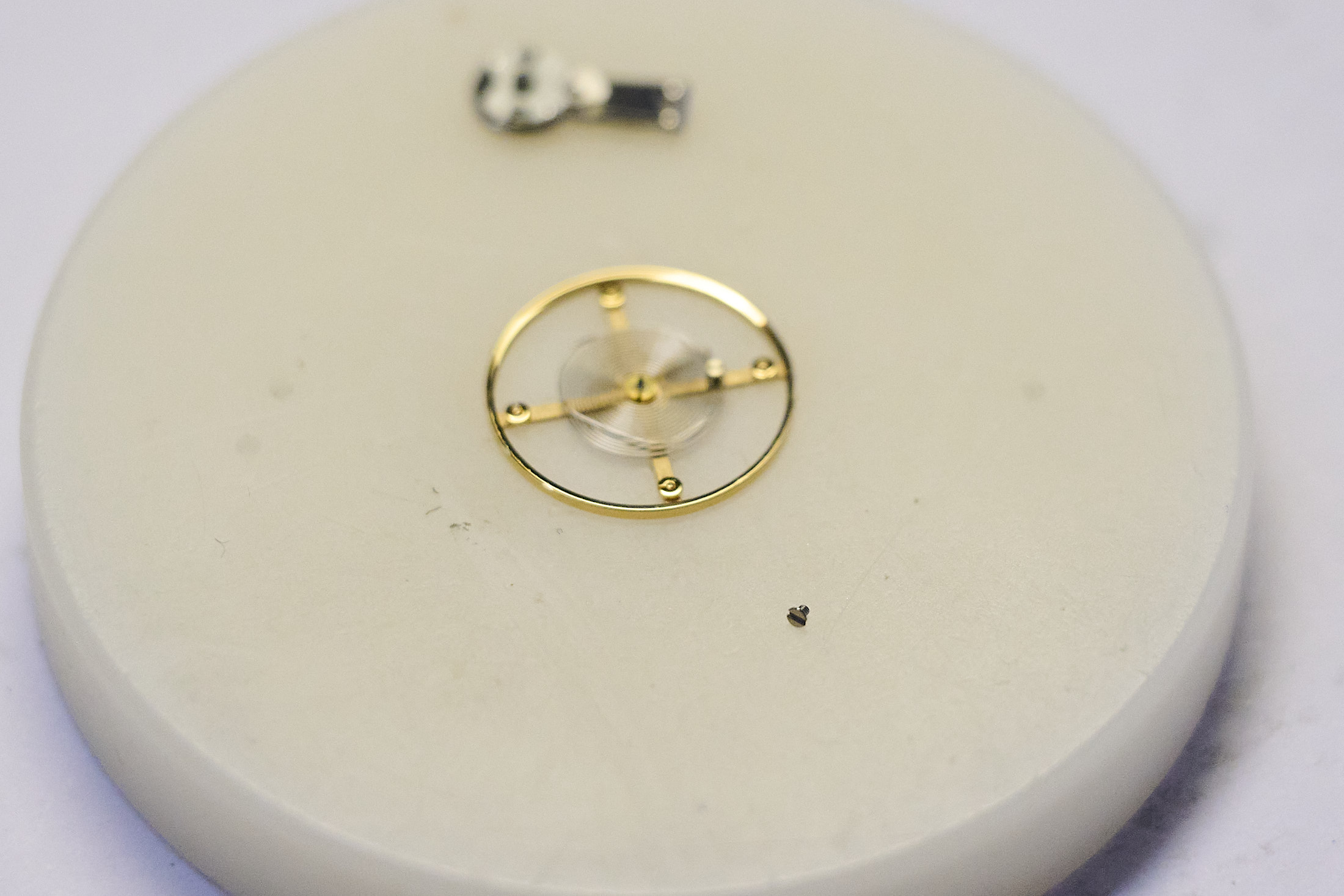

If you want a sense of how small of parts they're working with, this should help.

In the next room, another master watchmaker is assembling this unusual-looking movement.

Hands sit off to the side before being added.

Resulting in this watch, the FFC piece where the hand's gesture shows the time.

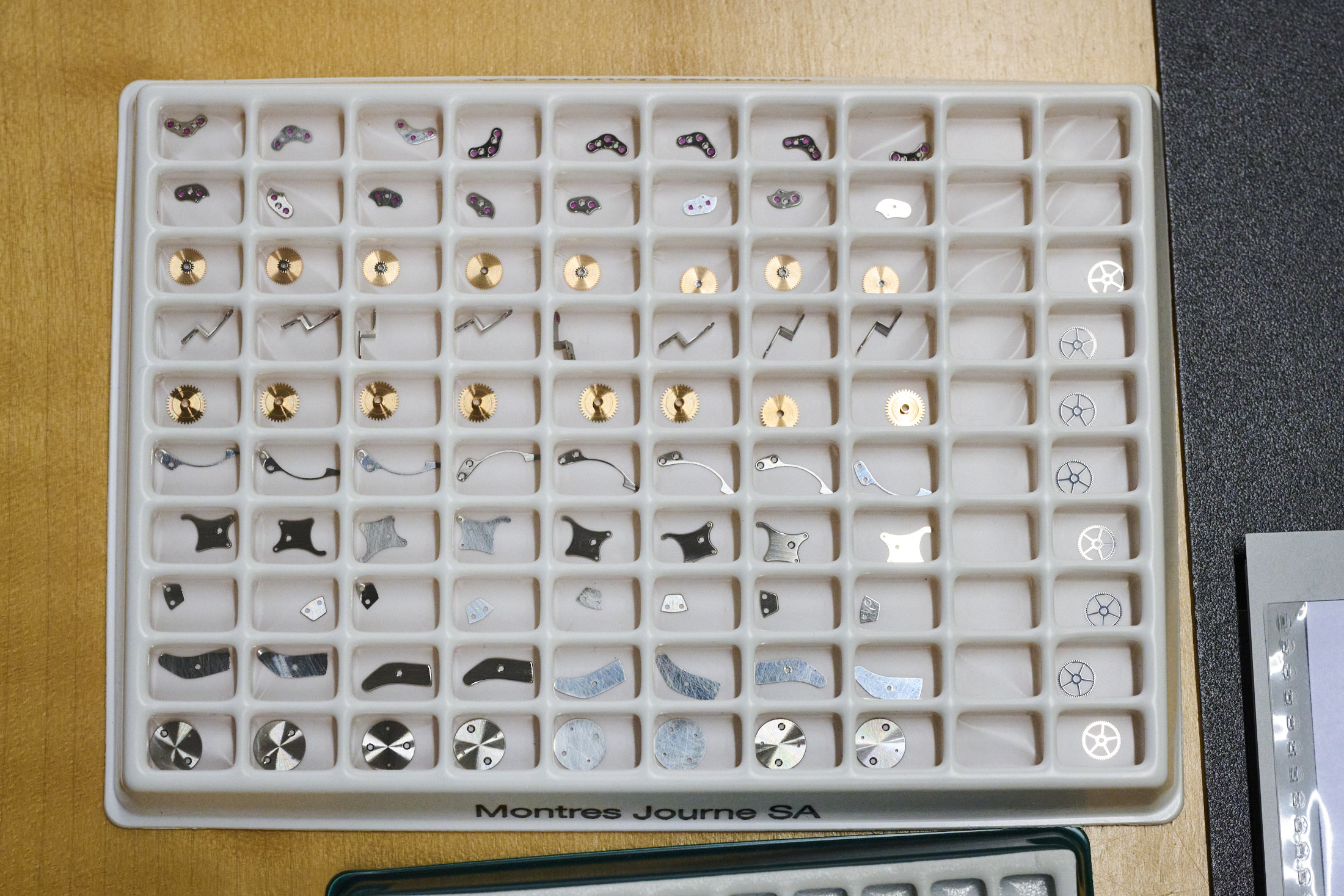

For movement assembly, kits of parts are gathered so watchmakers can make sure they have every piece they need and nothing is forgotten.

François-Paul has a very reserved office, not at the front of the building or in the largest room, but just enough space to do his work.

Les Cadraniers and Les Boîtiers de Genève - Meyrin, Switzerland

The stories of Les Cadraniers and Les Boîtiers de Genève go back to the early days of F.P. Journe. François-Paul made the dials for all his souscription models of the Tourbillon Souverain and Chronomètre à Résonance (and the Resonance's pre-souscription pieces). Though these pieces are some of the brand's most collectible, they're obviously not the best dial work in the brand's history. Journe quickly found the need to expand and improve his dial production while maintaining a level of independence. You could say that everything you see in Meyrin today came from those early days of Journe.

The entrance to the Les Cadraniers and Les Boîtiers de Genève facilities.

There are nearly endless benefits of owning your own dial and case manufacturing facilities, some of which I'll get to in a bit. But by controlling the brand's own supply, they inevitably avoid the kind of slowdowns that have plagued so many watchmakers who have had to rely on an ever-constricted flow from outside suppliers that can't keep up with increasing demand. Then there's the other obvious benefit. F.P. Journe can make exactly what it wants, how it wants when it wants, and to the standards it sets.

The current facilities for both companies opened last year after a three-year renovation and overhaul of the building they call home. The building, on rue de Veyrot, sits near a number of other watchmakers' factories (including La Fabrique du Temps) so it's not unusual to see other watch brands represented on wrists during lunch at one of the few restaurants nearby. The building Journe's facilities occupy previously sat empty for some time until they acquired it three years ago, stripped it to its core, and rebuilt it completely bespoke. To fit the needs of the brand, floors needed to be insulated against vibrations that could impact things like dial-making. Climate control and security are also all state-of-the-art.

Though the facilities in Meyrin share a single building, the two sub-companies operate completely siloed from each other. One main purpose is purely logistical: any work done in the case manufacturing facility (be it vibrations, metal particles, etc.) could adversely impact the fine tolerances of the dial manufacturing. But as we'll see in a bit, Le Cadraniers and Les Boîtiers de Genève serve two different client bases.

For François-Paul Journe, everything always starts with the dial. Even today, Journe is a one-man research and development department. Every idea worth exploring quickly gets disseminated to various departments, including an R&D dial design department at Le Cadraniers de Genève that takes each idea, explores the possibilities, and returns the results to F.P. Journe to share their findings. A number of my favorite movements from other manufacturers have less-than-beautiful dial designs. This is often an inherent issue with movement design – a movement layout necessitates subdials be placed in certain locations, sometimes squished in the center or lower on the dial, disrupting the visual balance. When starting with the dial and working toward the movement, designing the movement becomes harder, but the result will always look good on the wrist.

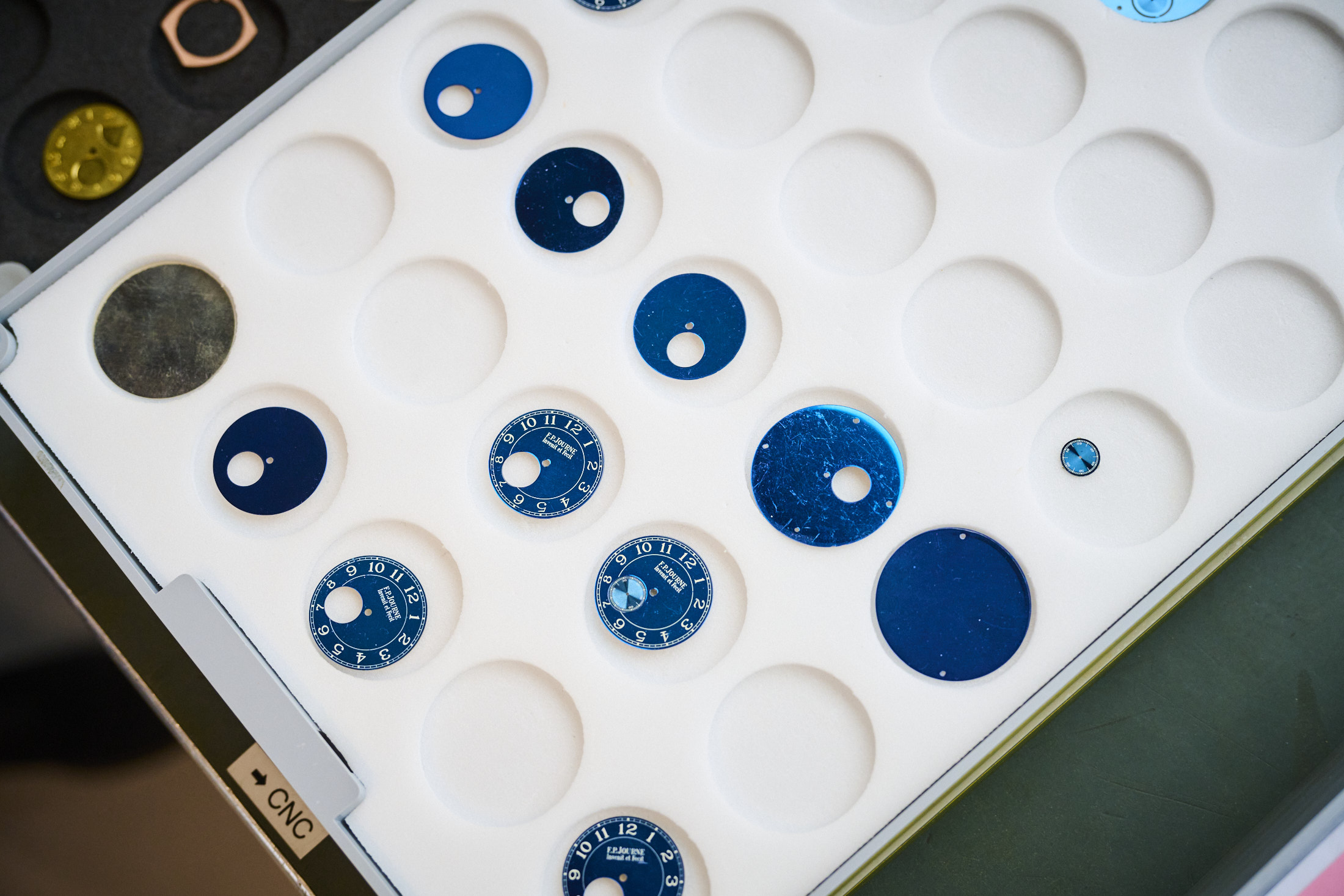

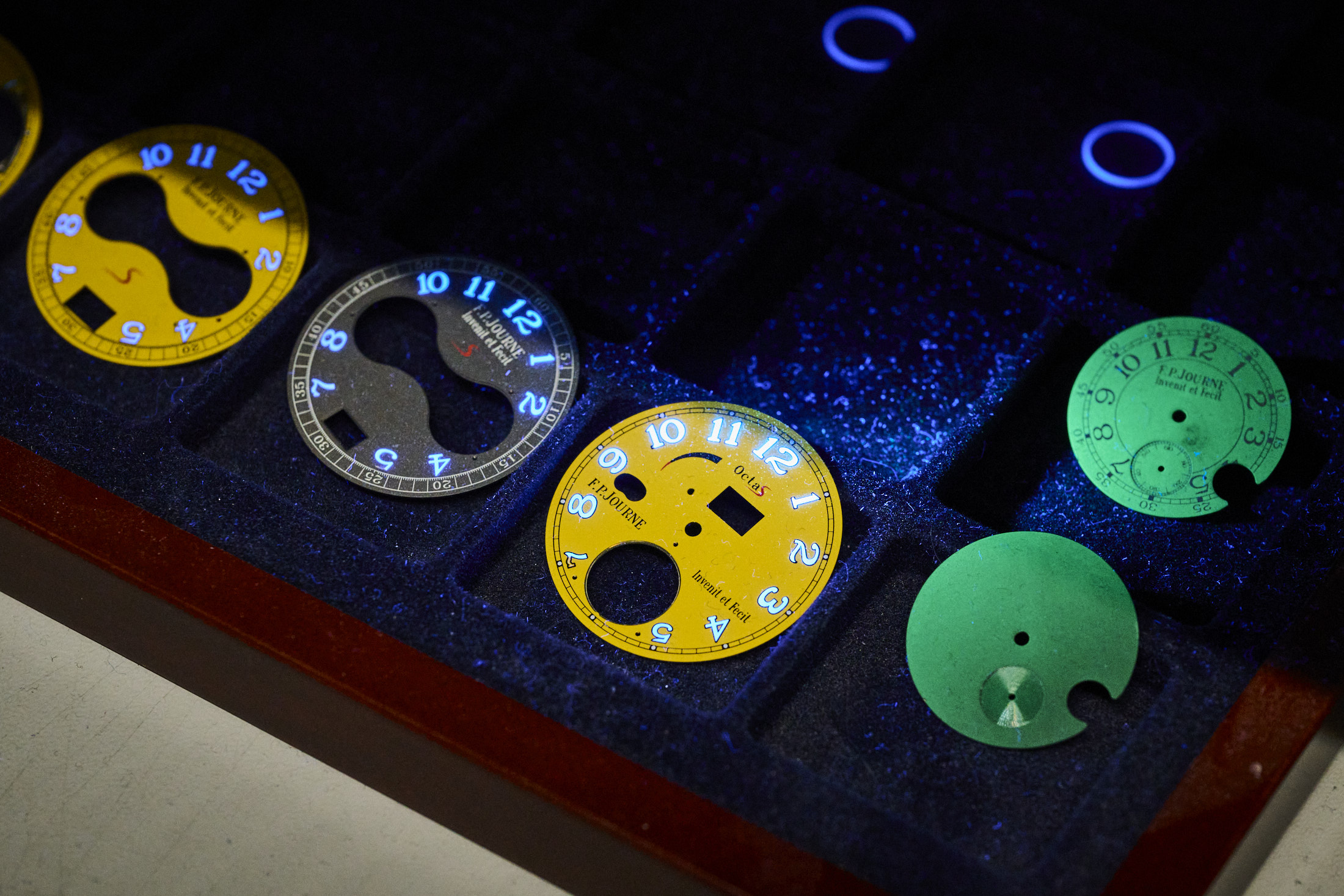

A variety of examples of what can be done at Les Cadraniers.

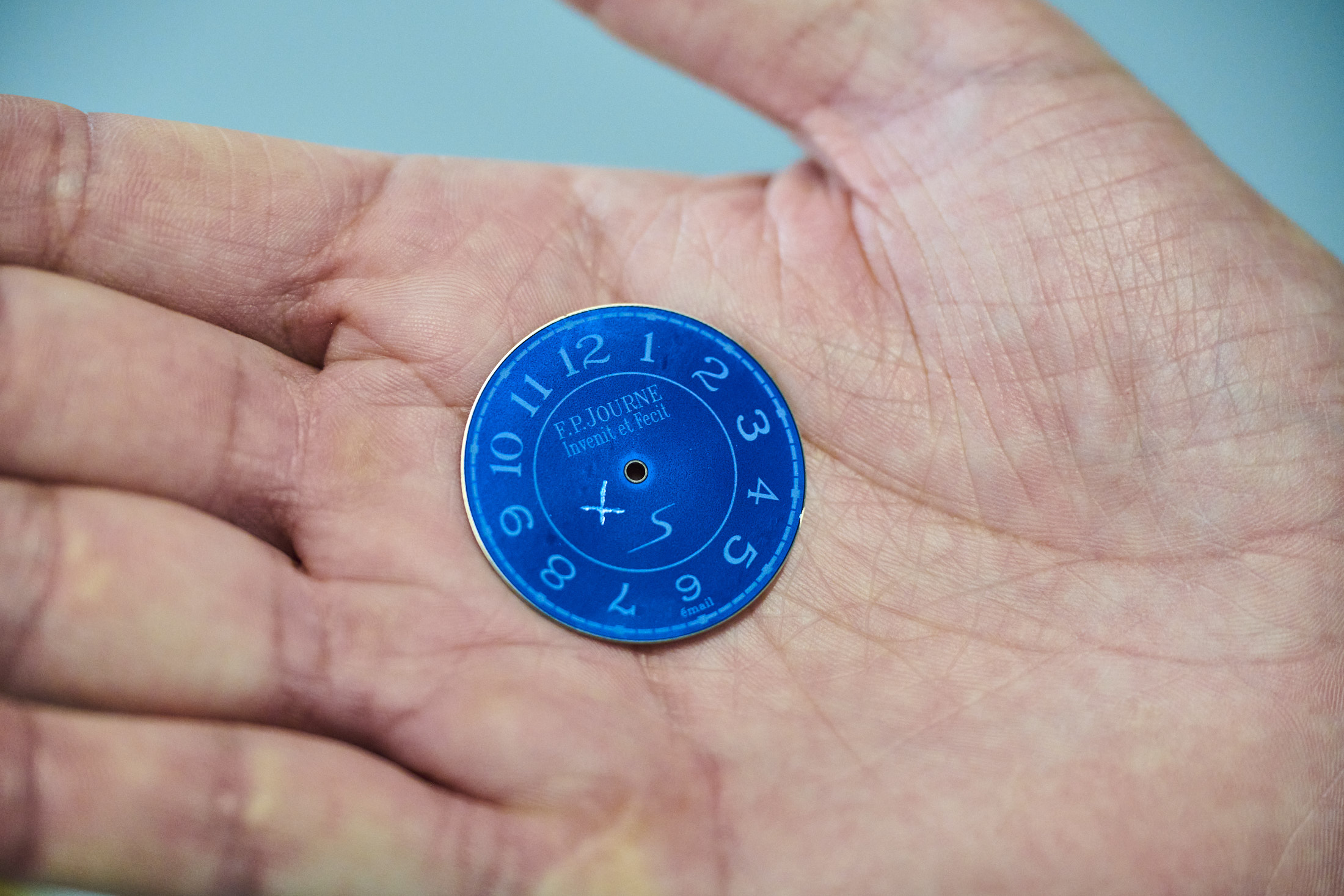

One of the most iconic dials in watchmaking, the Chronomètre Bleu is made up of several very fine layers of blue lacquer which are polished between firings. The failure rate is around 30% and the total production of Chronomètre Bleu has been reduced from a high of 200 pieces a year down to only around 50.

One of the most interesting things about Les Cadraniers isn't the work that it does for F.P. Journe, but the place of prominence it holds in the industry as one of the best high-end dial suppliers for the rest of the watch world. This all harkens back to the long and winding path Les Cadraniers has taken over its history and eventual independence under F.P. Journe.

After his early work with his own hand-made dials, F.P. Journe partnered with jeweler Harry Winston (which was then under Max Büsser's leadership) and watchmaker Cédric Johner to create Les Cadraniers in 2000, barely a year after the founding of F.P. Journe. Looking back on this move, what strikes me is that, like his early acquisition of the Janvier clock, Journe made bold (and frankly expensive) choices in the early days of his career, just two years after the founding of his brand. But they paid off. By 2012, his two other partners had left Les Cadraniers and Vacheron Constantin stepped in, taking a 50% stake in the business. In 2016, Journe bought out Vacheron, though the brand still remains a prominent client.

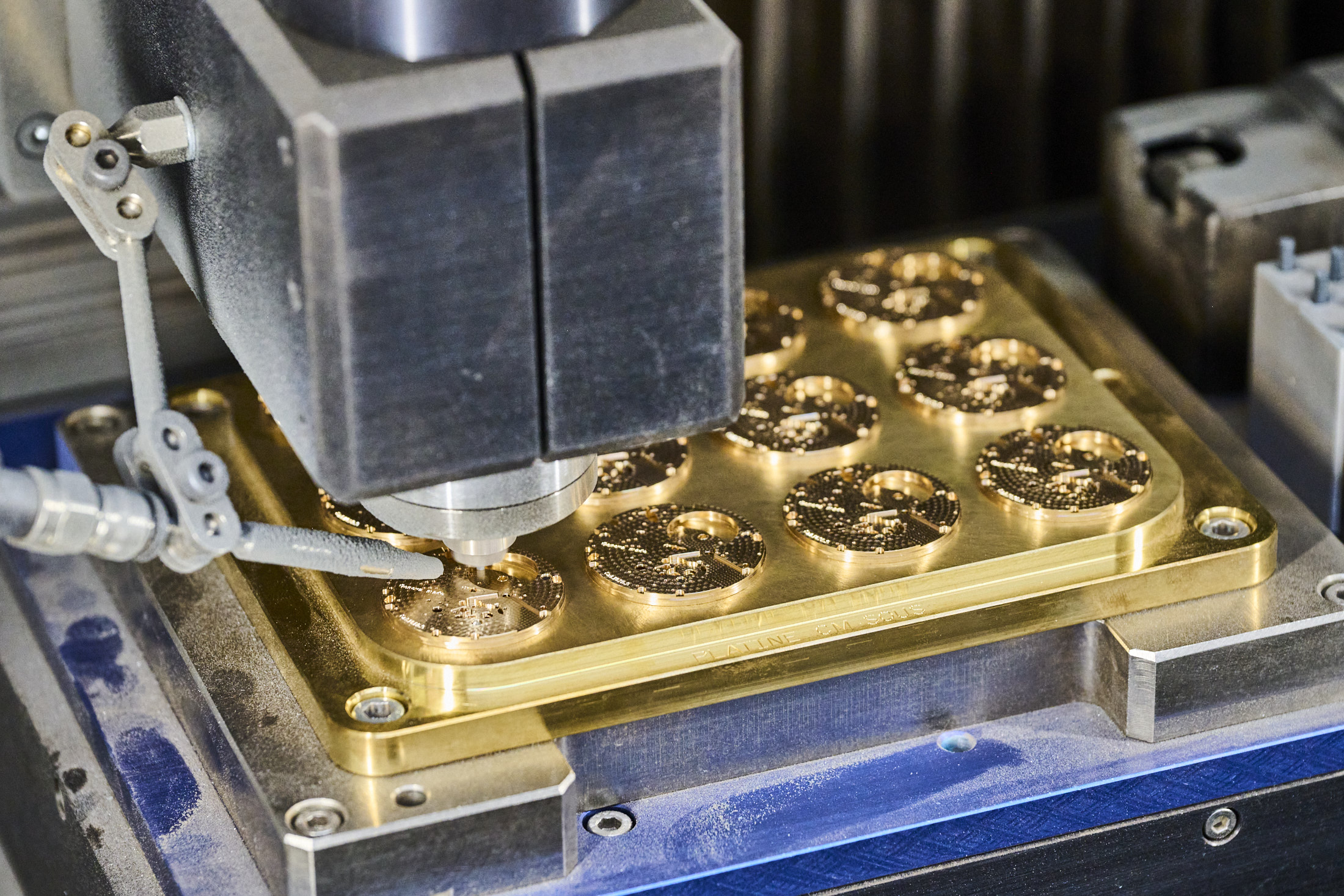

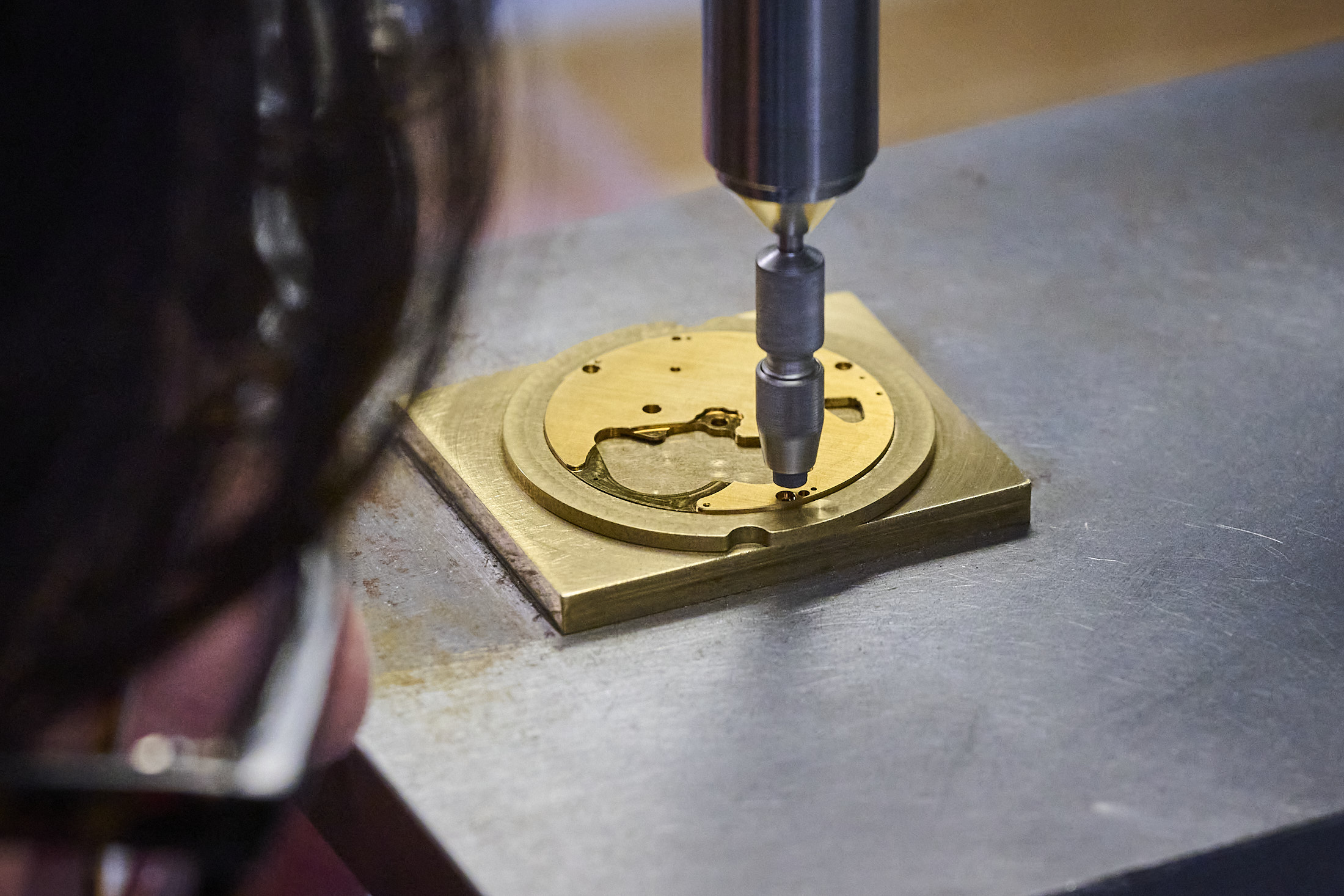

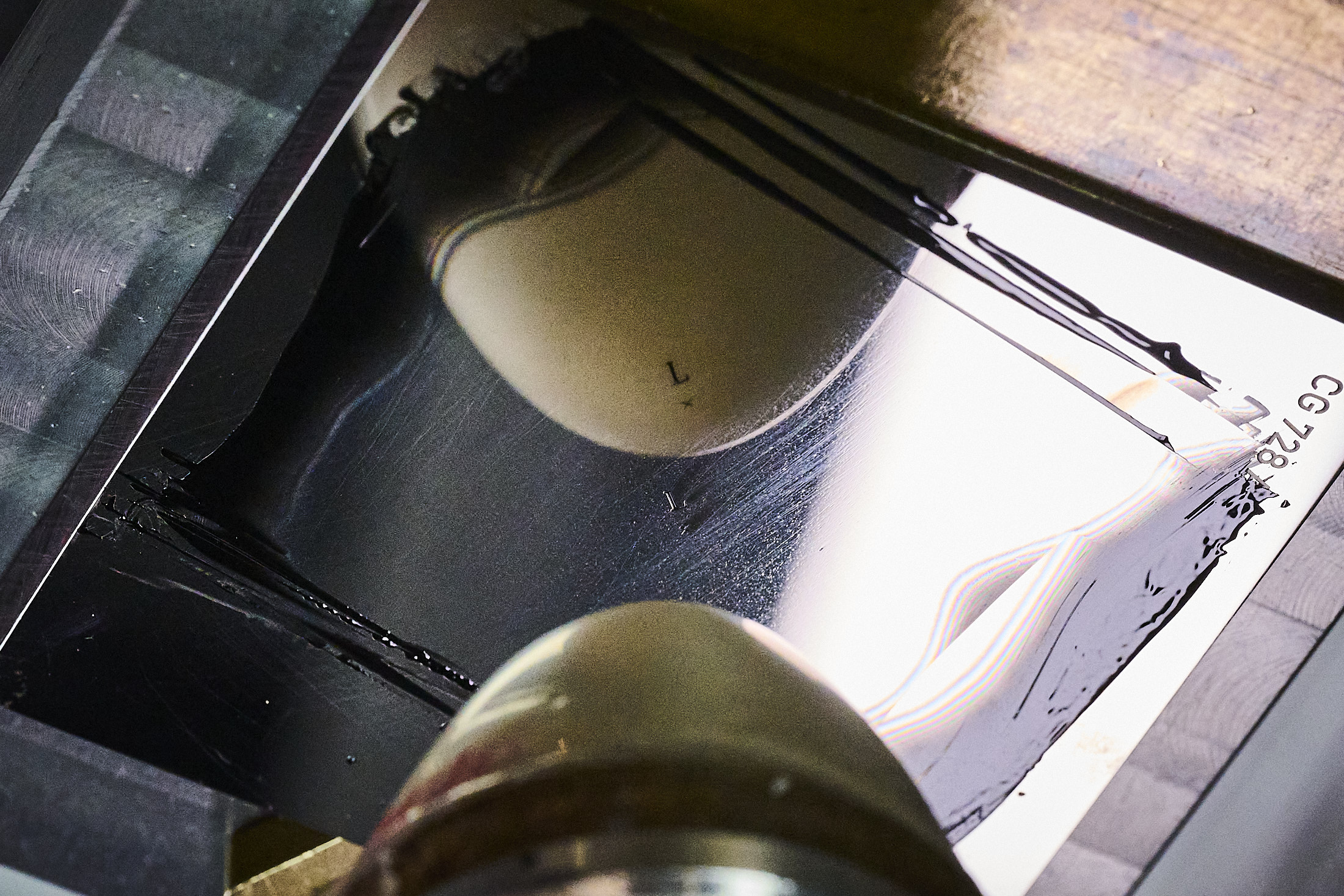

The team in this workshop will define the CNC machining sequences based on the technical drawings created by the technical office. F.P. Journe can machine parts (dials, counters, but also indexes and applied numbers) in all materials (brass, nickel, silver, gold, platinum, mother-of-pearl, etc.).

The CNC machine quickly interchanges tools, which employees must carefully monitor to ensure they remain within the standards and sharpness needed to continue quality production.

A number of tools were sitting out while a machine was worked on and tools were calibrated.

Just like with F.P. Journe's movements, the creation of dials at Les Cadraniers de Geneve is a balance of technology and handcraft. But the independence and technological prowess of the dial maker has allowed them to experiment and become an industry leader in a number of techniques. One of the most interesting, which you'll see shortly, is the company's skills with luminous materials. If you've seen a watch with three-dimensional lume with sharp shapes and that stand proud without surrounds, it's very possible that you're looking at Les Cadraniers work. It should be no surprise either that if you've ever enjoyed a fully-lumed dial (not just Journe's Élégante) that shines bright under UV light without dark patches causing blotches on the dial, that's probably something they've done as well.

Then there's the materials. You won't see brass dial plates in photos here. F.P. Journe is famous for its use of dials made from solid red and white gold, but Les Cadraniers also will use solid silver and German silver. While the process starts with CNC machines milling out plates, drilling holes for subdials, apertures, dial feet, and seats for numerals to be applied, even here there's a tremendous attention to detail, including beveling done to these holes. As the process moves forward, handcraft quickly becomes more and more important.

Bonding the material to the base before machining.

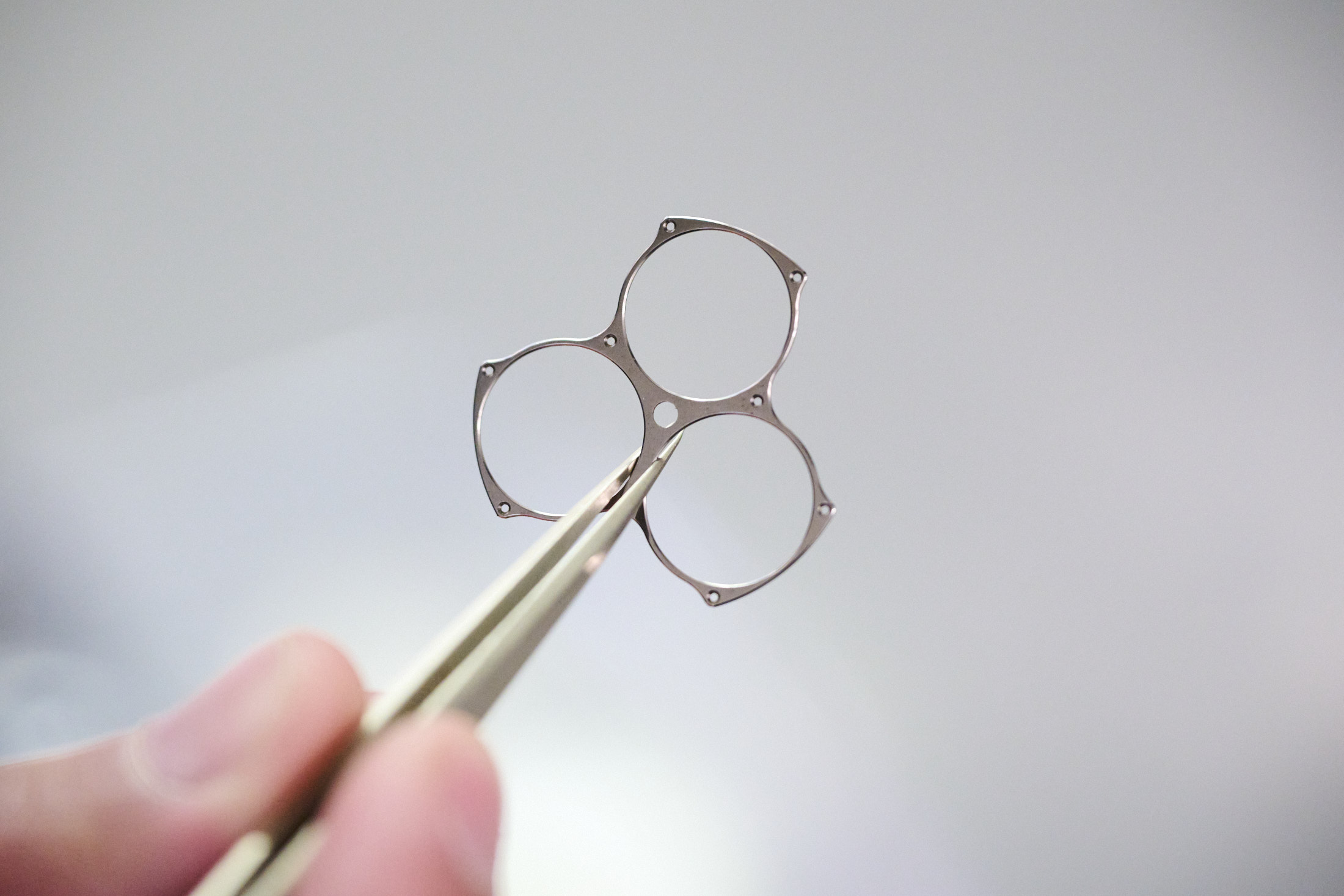

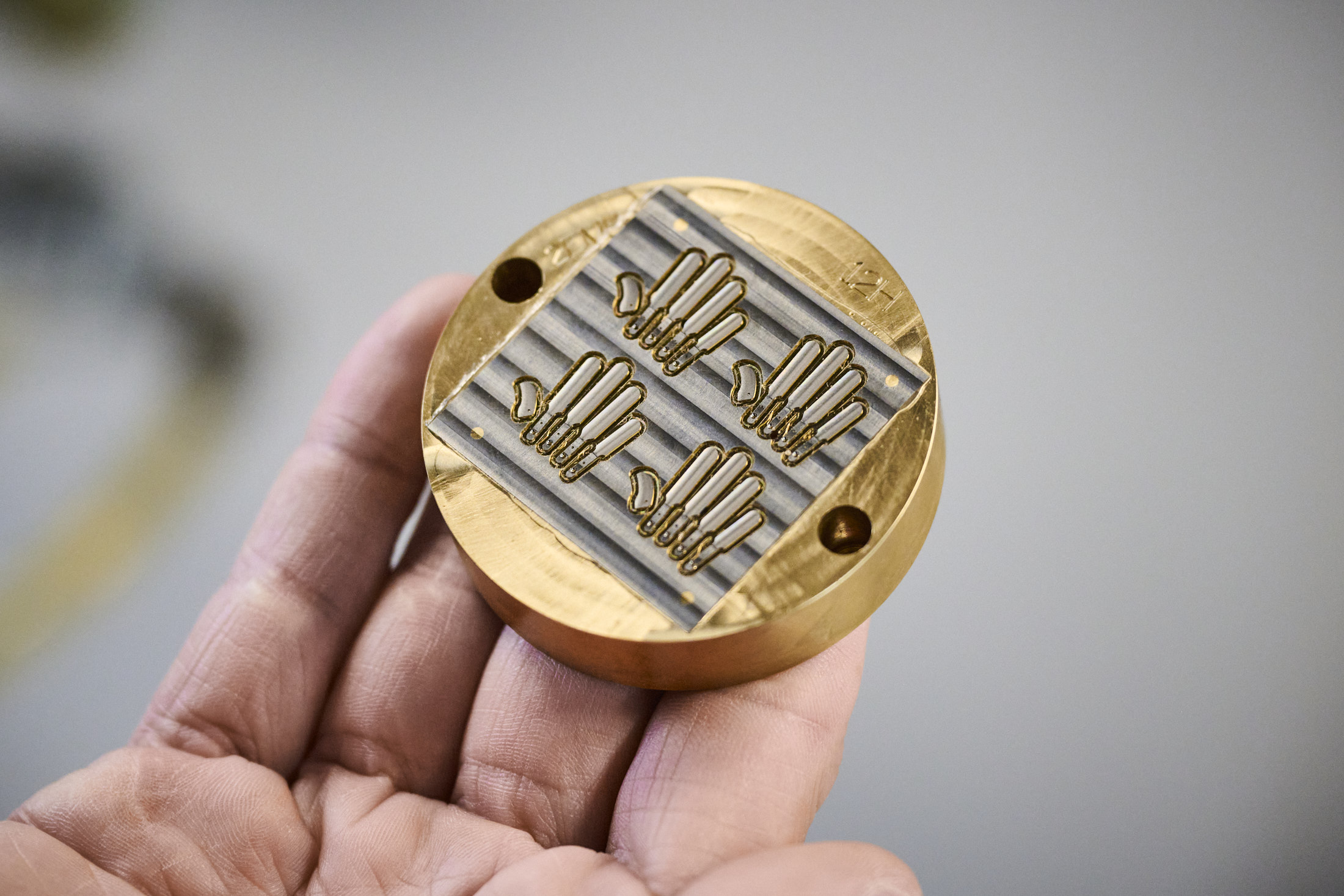

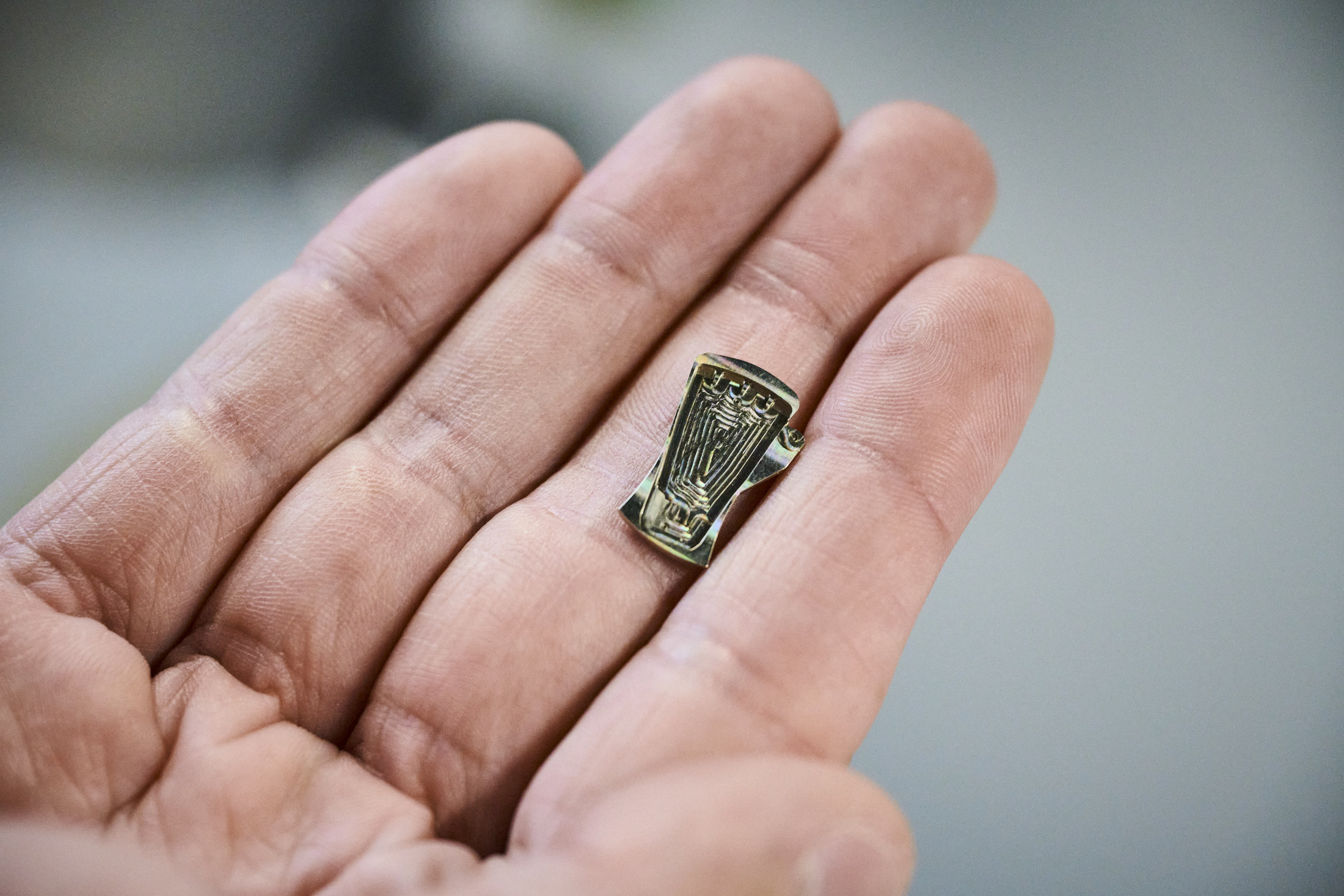

These are the milled titanium fingers for the FFC watch, with its unusual hand display of the time.

The milled hand for the FFC.

A support is being adjusted using a traditional machine.

Dial feet

Dial tolerances are incredibly thin – only 0.2mm to 0.4mm – so workers have to go through and check each dial multiple times throughout the process of finishing. No machinery is possible of verifying flatness to such a degree because the dials are already far advanced in the production process. The purpose of the blade is to check that the dial is flat, if necessary, rectify this by applying light pressure in the right places.

Polishing moon phase discs.

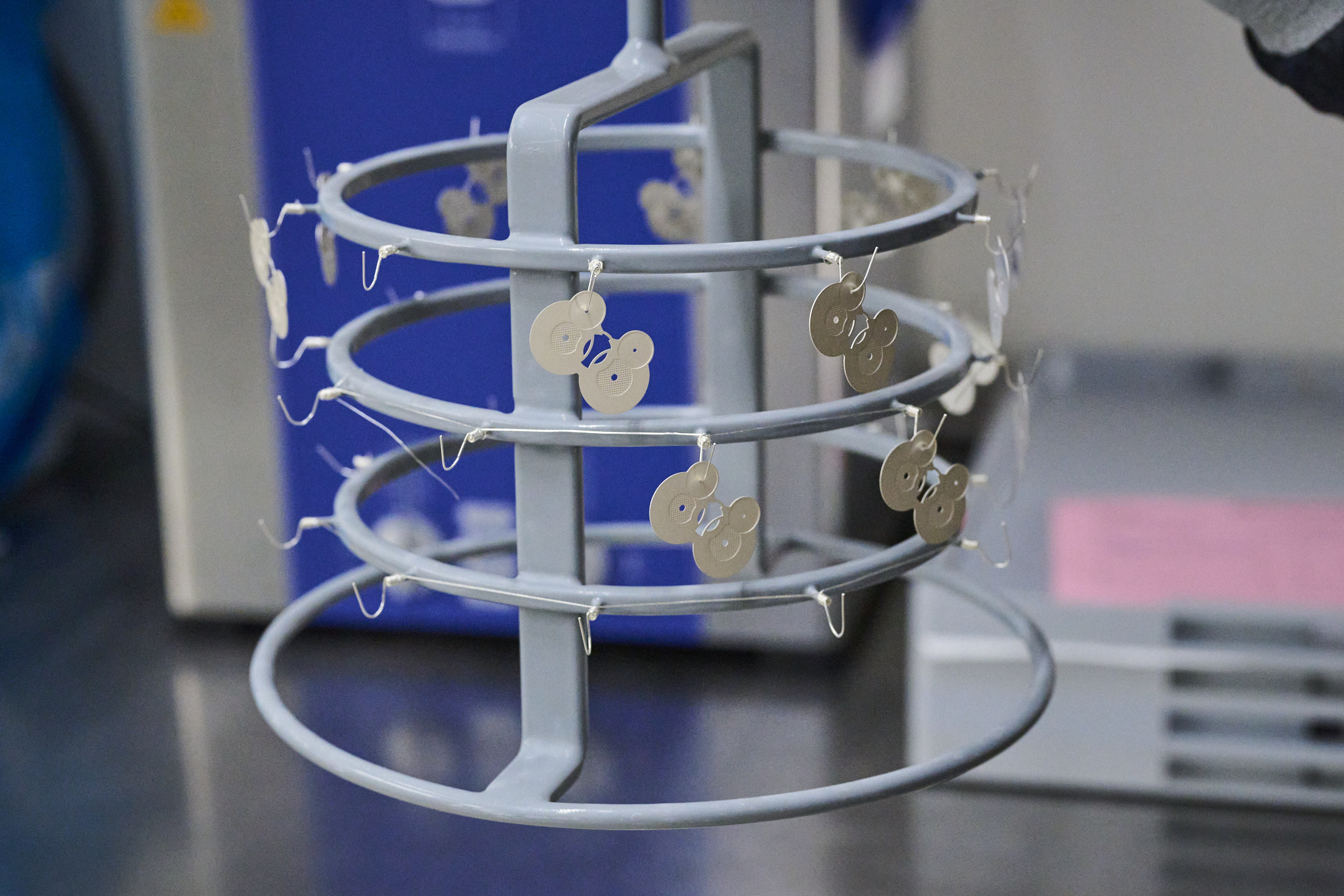

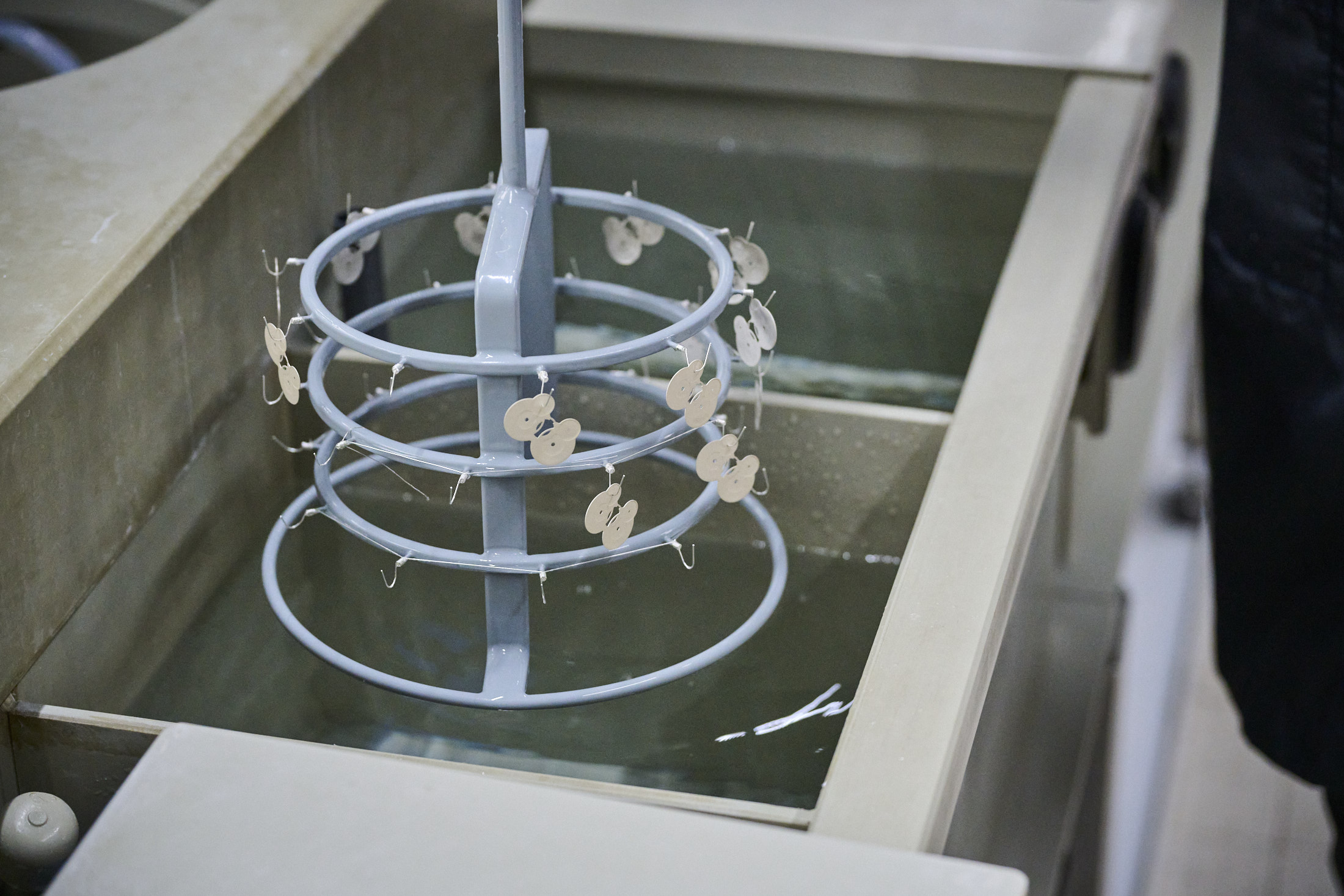

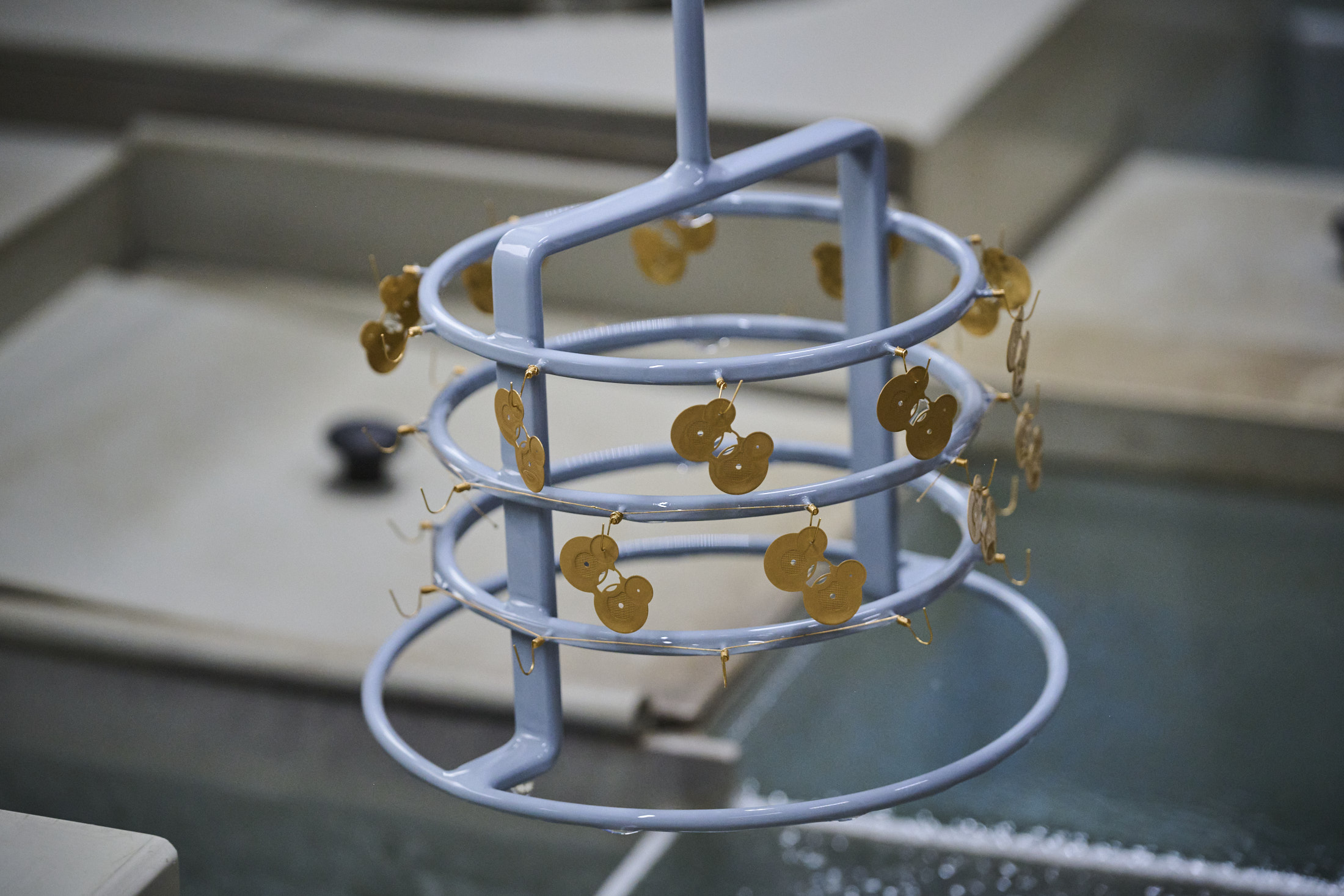

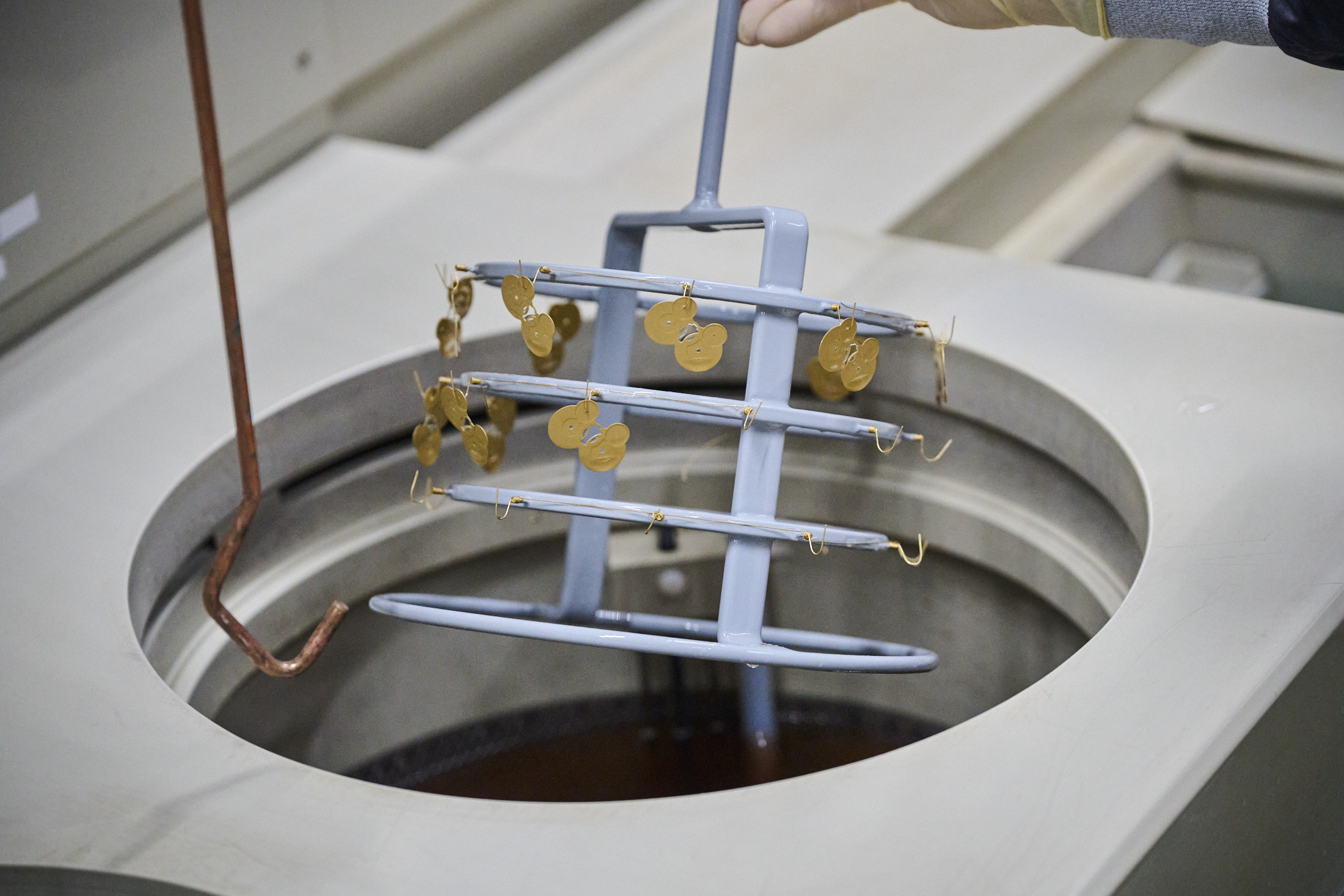

Moving on from the creation of the components, we visited the next workshop (of the 13 total at Les Cadraniers), where dials are subjected to a number of chemical baths in a delicate and intricately timed sequence. Depending on the dial (or in this case, subdial) workers will move hanging racks between different baths, washing them in-between, with the dials slowly rotating on a hanging hook. These dials are then gently washed between chemical baths to reduce potential contamination. We actually stayed in this workshop for quite a while, so you get to see how these subdials for the Chronomètre à Résonance change between each treatment.

Electroplating workshop, with baths developed specifically by Cadraniers de Genève

This is where the Chronomètre à Résonance subdials started when we arrived at the workshop.

First stop was an electro degreasing bath and then a wash, where the dials generally looked unchanged (which is a good thing).

The watches then went into (and here were pulled out of) a gold bath (which was labled with a scary skull and crossbones in case you couldn't read French to understand the word acide).

Next step (again, after a water bath) was an American nickle acid bath.

Then back in another 18k 3N yellow gold acidic bath.

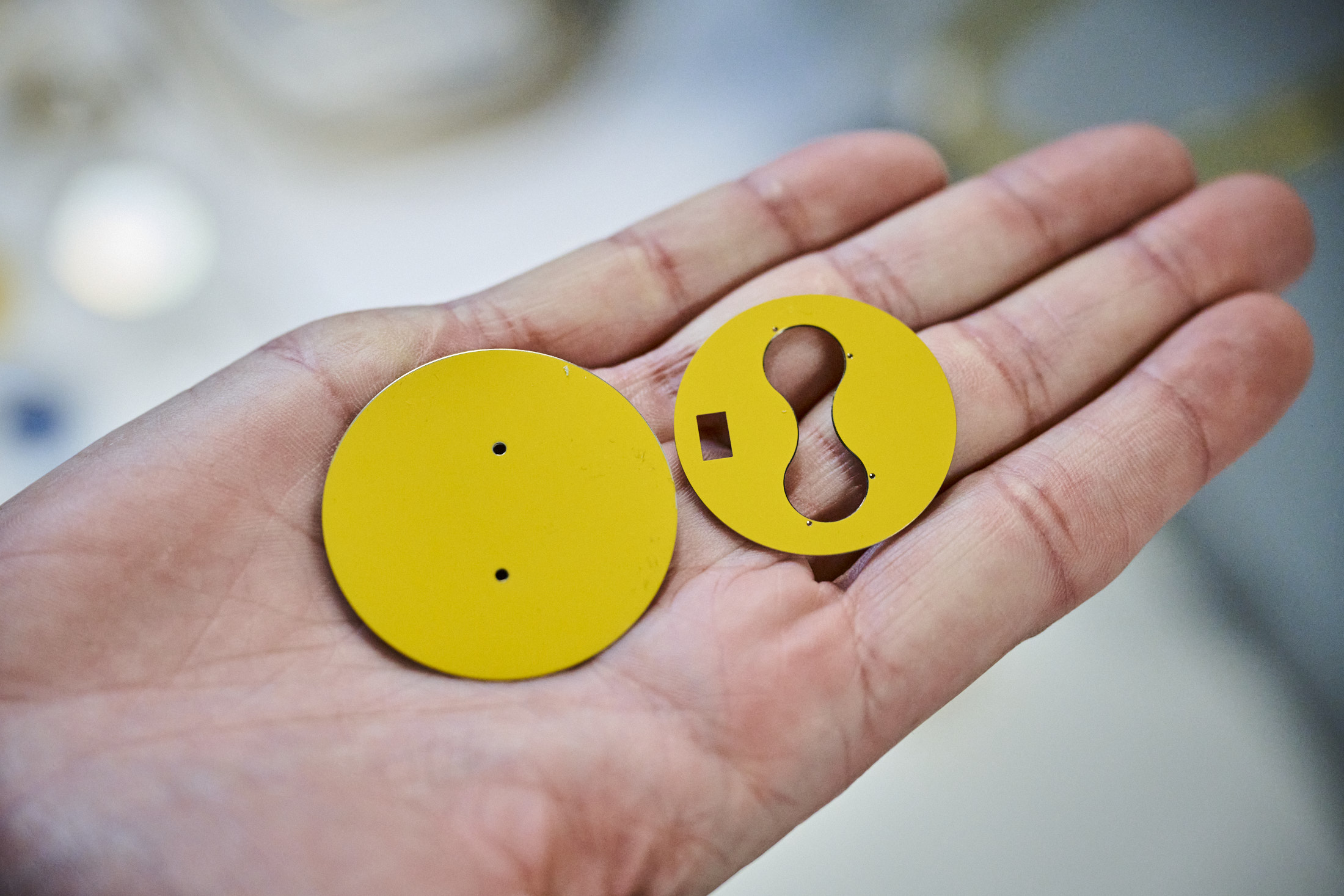

F.P. Journe very famously doesn't shy away from other dial materials and colors. Here you can see the yellow Aluminium alloy used for the lineSport collection.

They also can work in various forms of mother-of-pearl.

At the end of one hallway is the enameling workshop, where they are kind enough to put a large display above the workbench so you can see the work they're doing. Currently, beyond the Chronomètre Furtif Bleu, the only enameling work in the brand's production line is the Grand Feu enamel hour dial at 3 o'clock on the Tourbillon Souverain. As with other parts of Les Cadraniers, the enamel workshop uses their skills for orders from other brands.

This workshop includes enamelling, engraving, and setting. Their challenge is to develop innovations that respect the constraints of a dial, and then to produce these dials in small series.

The glass powder for enameling work is often incredibly rare and difficult to source, so shelves full of enamel is a dream for an artist.

A rejected dial attempt for the F.P. Journe Chronomètre Furtif Bleu Only Watch piece.

Slowly painting on the enamel.

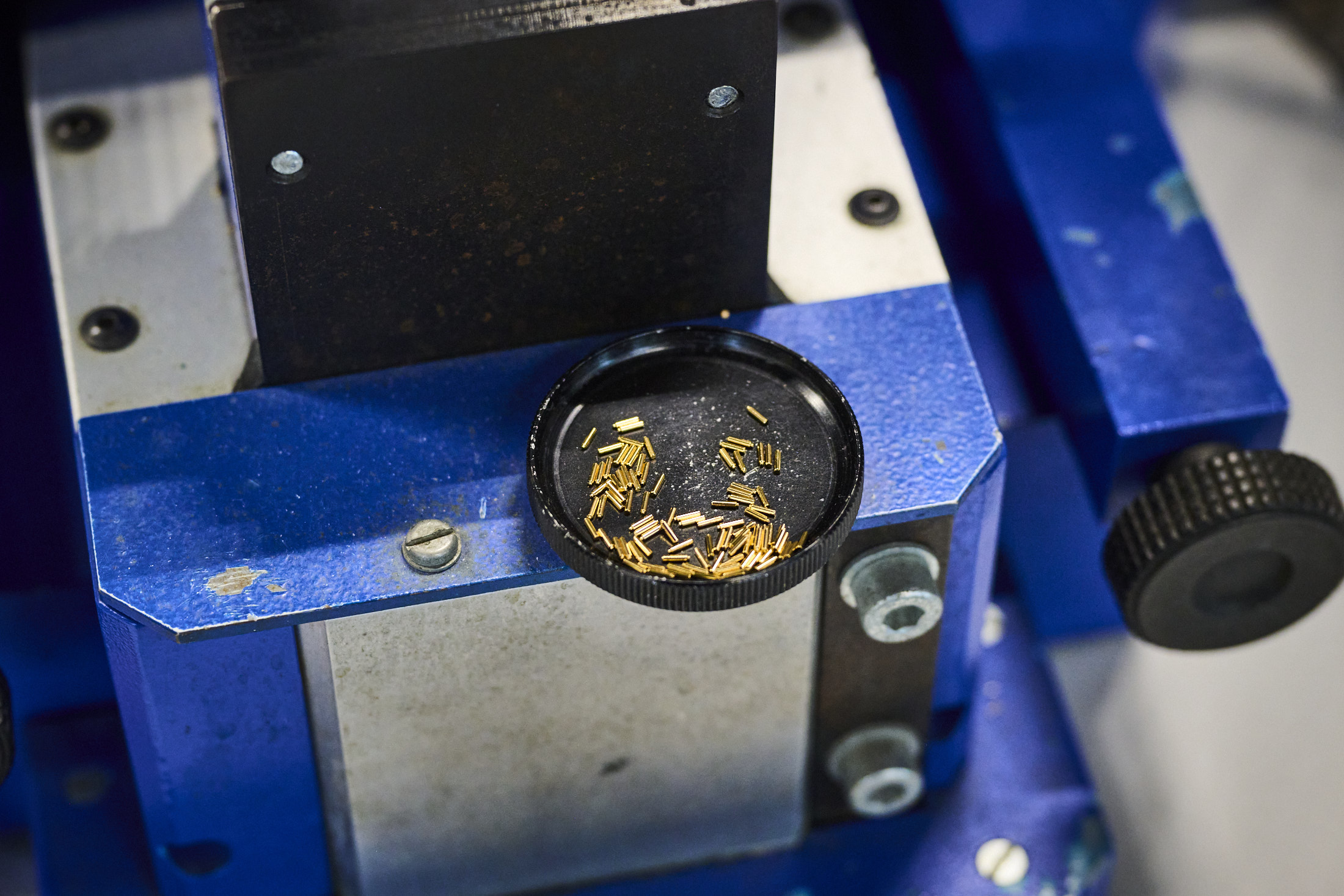

One of the most interesting (and headache-inducing) tasks to watch was the sorting and application of dial numerals. The numerals (other parts of the dials assembled in the appliqué department) are all cut out with CNC machines and then hand polished. To assemble the watch, you first have to find the numerals in a tray full of similar-colored metal material. They're then sorted into rows so the right numeral can easily be found later before they're gently applied. For some reason, this reminded me of trying to spell out words in your alphabet soup.

As a lover of good stories, I was probably most impressed by Dinh-Sang Ngo, an employee who has been working in the tampographie (or pad-printing) department for F.P. Journe (and other brands) since 2000 after starting at Stern Frères more than 40 years ago. Until recently, he was responsible for nearly every pad-printed dial from F.P. Journe, though as he's getting older, the brand has brought on someone else to learn the ropes. That said, Ngo works differently than his apprentice. Using stamps that he has hand-made out of natural animal gelatin, Ngo carefully aligns each dial by sight, transfers the ink, and then stamps the dial at least five times. Across from his bench the same thing is done by the apprentice but using calibrated machines with silicon molds, requiring less "feel" for the process.

Dinh-Sang Ngo has to find a different-shaped container for each new traditional gelatin he creates. For a single dial, he needs at least three different pads to make each impression (logo, numerals, power reserve, etc.).

The reflection of the leap year indicator for the Quantième Perpétuel.

On the tour, the brand was most restrictive for photos when we reached the printing area for luminous materials. The mix of materials used and how they're applied to (or integrated into) the dial is a closely guarded secret, but I could have spent hours in the space discussing their work with the head of the department. It was fascinating to hear how difficult the process is and how surprised even the materials manufacturers who make the lume are when they find out what F.P. Journe is capable of.

Compared to the complexity of Les Cadraniers, the sister company of Les Boîtiers de Genève (which largely occupies the lower floors of the Meyrin facility) seems relatively simple by comparison. The case-making facility doesn't do any work for outside companies, so the company's full production is dedicated to F.P. Journe. Even then, the expensive CNC machines don't run 24/7 like they might at other companies. But there are still plenty of parts of the process that require a human touch.

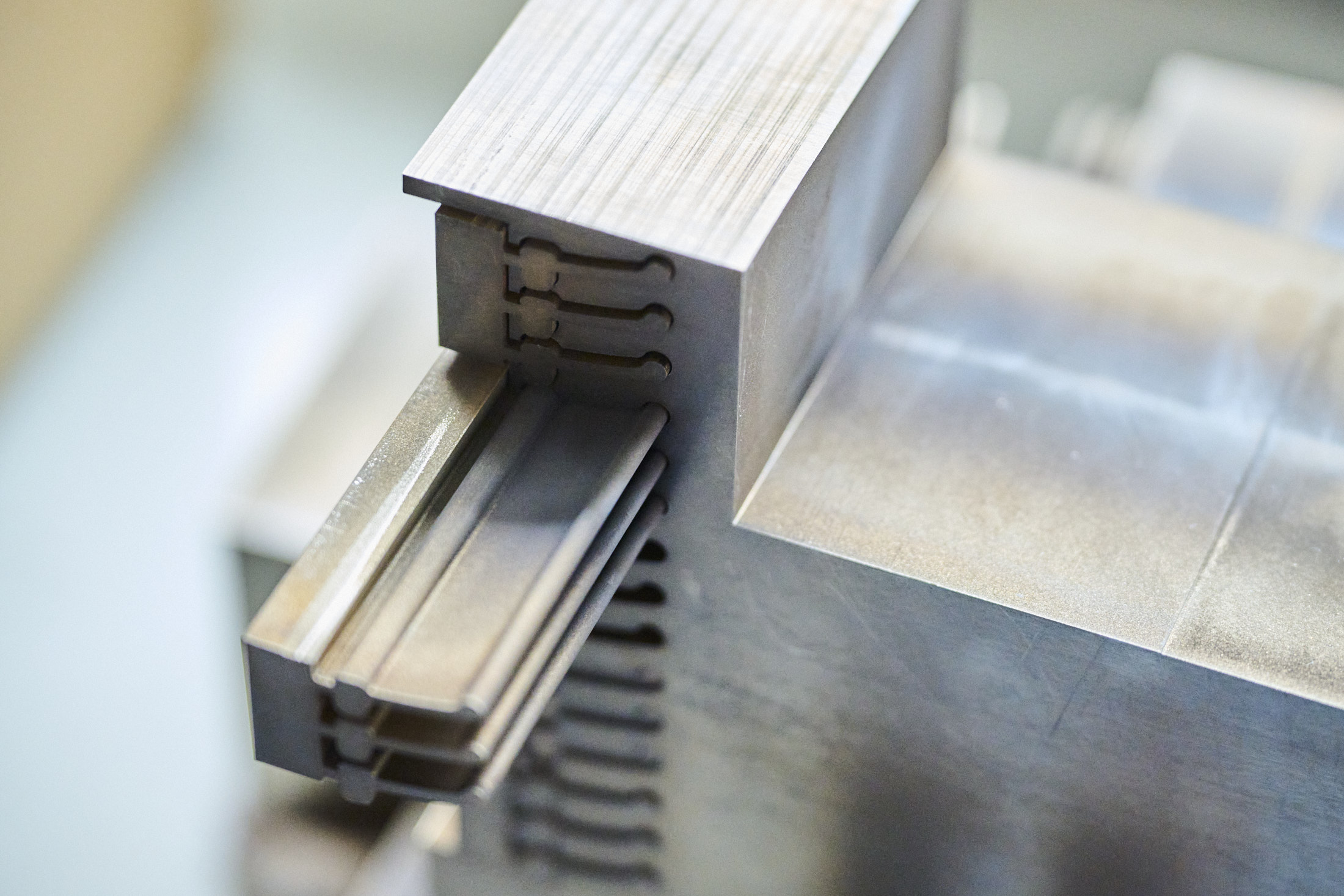

CNC machines on the basement level at Les Boîtiers de Genève.

Les Boîtiers de Genève has been in operation since 2012 but the technology used here is being continually updated. While several of the machines I saw were bought for the opening of the new facility in 2023, another had been delivered just a few weeks prior and just gone through its calibration to get to work crafting new cases. The newer the CNC machines, the better the tolerances that are allowed. Tools need to be continually monitored because each material used by the brand – gold, platinum, titanium, steel, and tantalum – all wear down the parts at different rates. It's been talked about ad nauseam, but tantalum requires the most effort because of its incredibly ductile properties. That's why F.P. Journe is one of the few brands willing to use it and the first to make a full bracelet from the material with the Chronomètre Furtif Bleu.

Raw materials are slowly formed out to make the shape of the case and refined bit by bit. Most often you'll find a three-piece case construction with back, midcase, and bezel, all joined together with screws (back to middle) or lasering/hand-soldering. It's also worth noting that, even though you won't see it here, F.P. Journe also produces all the parts of their bracelets (whether their lineSport titanium or gold bracelets or the additional "on request" bracelets in rose or platinum for their classic line) here at Les Boîters de Genève, another component of the brand's skillset that many other brands have outsourced.

The CNC machine hard at work.

Once again you can see the electro-erosion capabilities that could out material to make buckles in batches.

Milled out cases in gold.

These larger platinum cases are made for the Tourbillon Souverain set with 22.5 carats of 93 baguette diamonds.

The workstation for hand-done case soldering over an open flame. Unfortunately, we didn't get a demonstration that day, but from the images I've seen, it's certainly a dramatic scene. While 90% of the brand's cases are aligned using lasers and then joined in a soldering oven, more technical and difficult cases like the Astronomic Souverain are still completed with traditional open-flame soldering.

Sandblasting facilities on the lower floor, far from the rest of the manufacturing, allow certain finishes like the ones found on the lineSport collection.

Of course, hand finishing is key and comes down to touch, feel, and experience. All the cases are hand-finished on polishing wheels in one of the largest areas at the case manufacture. The wheels have a vacuum attached which will suck in any dust or particulate and both keep the facility clean but keep the workers from inhaling materials.

Buckles are milled at the facility and before being finished by hand.

As my visit to F.P. Journe's facilities drew to a close, I couldn't help but feel a renewed interest in the brand. I'm lucky to have several friends who count themselves among Journe's collector community, one that is probably the most tightly knit and carefully fostered of any brand. But with the increased demand over the past few years, the idea of Journe as an attainable brand has slightly drifted away.

After seeing the facilities for myself, I left feeling the same magic I felt when I handled my first early brass movement Résonance; it was like holding a piece of someone's genius laid out intricately in front of me. This time, I was wildly impressed that all of the manufacturing I was shown was the result of a singular mind who grew a company from small-batch bespoke timepieces to something far more grand while keeping the best of what a watch-lover would look for. Some of the decisions – the refusal to expand production and to eschew some of the intricate finishing that other brands have put their stock in – might seem counterintuitive. But when you see all the parts of one person's decisions result in one of the biggest powerhouses in independent watchmaking, it gives me a bit of hope. F.P. Journe could very well have remained far smaller, making watches at a scale like Dufour or Smith, but instead, he's blazed a path for other watchmakers who might care to follow suit and grow while making some incredible watches along the way.

For more information on F.P. Journe, visit the brand's website.

Top Discussions

Introducing TAG Heuer Refreshes The Aquaracer Professional 300

Auctions Sylvester Stallone's Patek Philippe Grandmaster Chime Leads New York Auction Week

Introducing Oris Turns The Divers Sixty-Five All-Black For Its 2024 Hölstein Edition